For a Crystal Clear Finish

Specializing in the design and production of tack cloths for professional uses.

Specializing in the design and production of tack cloths for professional uses.

Bond Corp. is the world’s only major tack cloth manufacturer that specializes solely in the design and production for professional uses.

For over 75 years, a wide variety of industry professionals have relied upon Bond® Tack Cloth to ensure that their products have the highest quality finish possible… a smooth, unblemished, Crystal clear finish that exceeds your expectations!

Bond Corp. is the manufacturer of Crystal® brand tack cloth.

Bond Corp. is dedicated to being the highest quality manufacturer and supplier of tack cloth and related products for the surface preparation industry worldwide. Quality means meeting customers present and future needs, recognizing that customers' exist both within the company and outside the company.

We know that the true value of our product is in its ability to perform properly in your particular application the first time, every time. That’s why our Application Engineers work closely with your finishing department to ensure that the right product elements, Tack Formula, Tack Weight, Material and Packaging are properly combined to trap and remove the dirt that other brands leave behind.

It's no wonder why Bond® Tack Cloth and Crystal® brand tack cloths enjoy the industry’s strongest customer brand loyalty

Bond Corp.’s product superiority is a direct result of the combination of high-quality materials, application-specific formulas and our tight specification manufacturing process. Our exclusive ‘thermoset’ process sets a quality standard only Bond® Tack Cloth is manufactured under and adheres to. Using a high temperature and pressure tack ‘thermoset’ impregnation process guarantees a shelf and working life that other brands simply can’t match. Thermosetting also significantly reduces invisible residue buildup that may react with other finishing materials to cause coating defects such as marring, streaking and fisheyes. The Bond® Tack cloth and Crystal® brand has a reputation for product reliability that is unsurpassed and sure to please your most demanding customers.

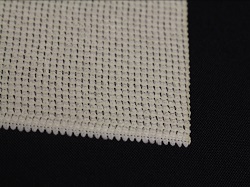

Materials are available to suit every need. We only use the highest grades of bleached woven cotton and knit polyester. This ensures that each piece of Bond® Tack Cloth will resist fraying, drying, hardening, snagging and linting longer than any other brand. A full range of cotton meshes (threads per square inch) are available including 28/24, 24/20, 20/16 and 20/12 to best suit your specific application.

In addition, two PolyKnit materials are also available. This synthetic, polyester based fabric is a continuous knit filament with a knitted selvedge which is hotwire-cut to eliminate contamination from loose or frayed fibers. This has become the new standard in the automotive industry.

Choosing the correct and right amount of ‘tack’ for your specific application is an important quality consideration. Our wide variety of unique, application-specific formulas are all designed and manufactured in our factory by highly skilled technicians who appreciate the special finishing challenges you may face.

Too much “tack” can cause invisible residue buildup which can react with paints and varnishes. Too little and your finish will be contaminated with unwanted particulates. Getting it just right is why Bond technicians have developed a full range of cloth treatments. From Lite & Dry to Extra Tacky, we have the right treatment and formula for the most demanding applications.

Prep Wipes dramatically reduces paint defects, improves paint adhesion and eliminates static electricity on prepared surfaces. Single-stage wiping system greatly increases productivity. Uniform surface conditioning with metered fluid release and cleans better than aqueous or organic solvents alone. Reduces shop waste and solvent use. 6 pouches with 50 wipers/pouch. A safety lock case is also available.

Whether it’s rolls, cut bulk or individual bags, our products are packaged to ensure the highest economics, greatest convenience and unsurpassed cleanliness.

Rolls are available in all of the cotton meshes. Rolls are 150 yards long, 36 inches wide, folded down to a 4-ply.

Please Note: Polyknits are not available in roll form.

Cut Bulk are 100 pieces per bag. Each piece of cotton tack cloth is 36 inches wide, folded down to a 4-ply and cut to an 18-inch length. Our Polyknit is a single ply nominal 9-inch width and cut to an 18-inch length. We bulk pack the shipping cartons for the most economical count for shipping. We offer single boxes for an additional charge.

Individual bags are 1 piece per bag and 100 pieces per carton. Each piece of tack cloth is 36 inches wide, folded down to a 4-ply and cut to an 18-inch piece then folded into a pad.

We have several career opportunity that you can apply for

Job Description:

We are hiring a production machine operators for our

manufacturing plant. This opportunity is perfect for the individual who likes

working with their hands, setting up and adjusting machinery and equipment to

run safely, productively, smoothly, and efficiently. You will be responsible

for operating and maintaining equipment that produces various grades and types

of tack cloths. A great Bond Corp. machine operator is reliable and able to

work with attention to detail and upholds our safety standards. Fast-paced

on-the-job training will require a willingness to learn and to work closely

with other experienced team members.

Responsibilities:

• Set up machines to start a production run

• Control and adjust machine settings based on safety and

quality standards

• Fix minor mechanical issues that might occur

• Check quality to prevent any machine-related mistakes or

flaws

• Recording accurate data on written reports

• Verify control and compliance to weight standards

• Batch mixing of non-toxic chemicals

• Perform cleaning, inspection, and preventive maintenance

tasks as required

• Maintain a clean and safe work area at all times

Skills / Requirements:

• One year of experience as machine operator preferred, not

required

• Understanding of operational processes and procedures

• Adherence to health and safety regulations

• Organizational skills

• Basic math skills

• Attention to detail

• Teamwork and communication skills

• Proficiency with hand & cleaning tools, including

industrial shears

4237 West Ann Lurie Place

Chicago, IL 60632

Phone 312-226-5535

Phone 800-253-2663

Fax 312-226-8099

info@bondcorp.com